Distillation techniques:

History of steam distillation:

1. Direct fire, “feu nu”

The first steam distillation stills were filled with water, direct fire was used to obtain the steam.

This technique was used until the end of the 19 Th Century , the only difference was that the herbs did not soaked

into the water anymore, but were separated with a “grille”.

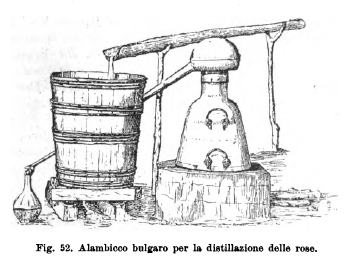

You can still see this kind of still, usually in developing countries.

Old still, France, direct fire

Still, India

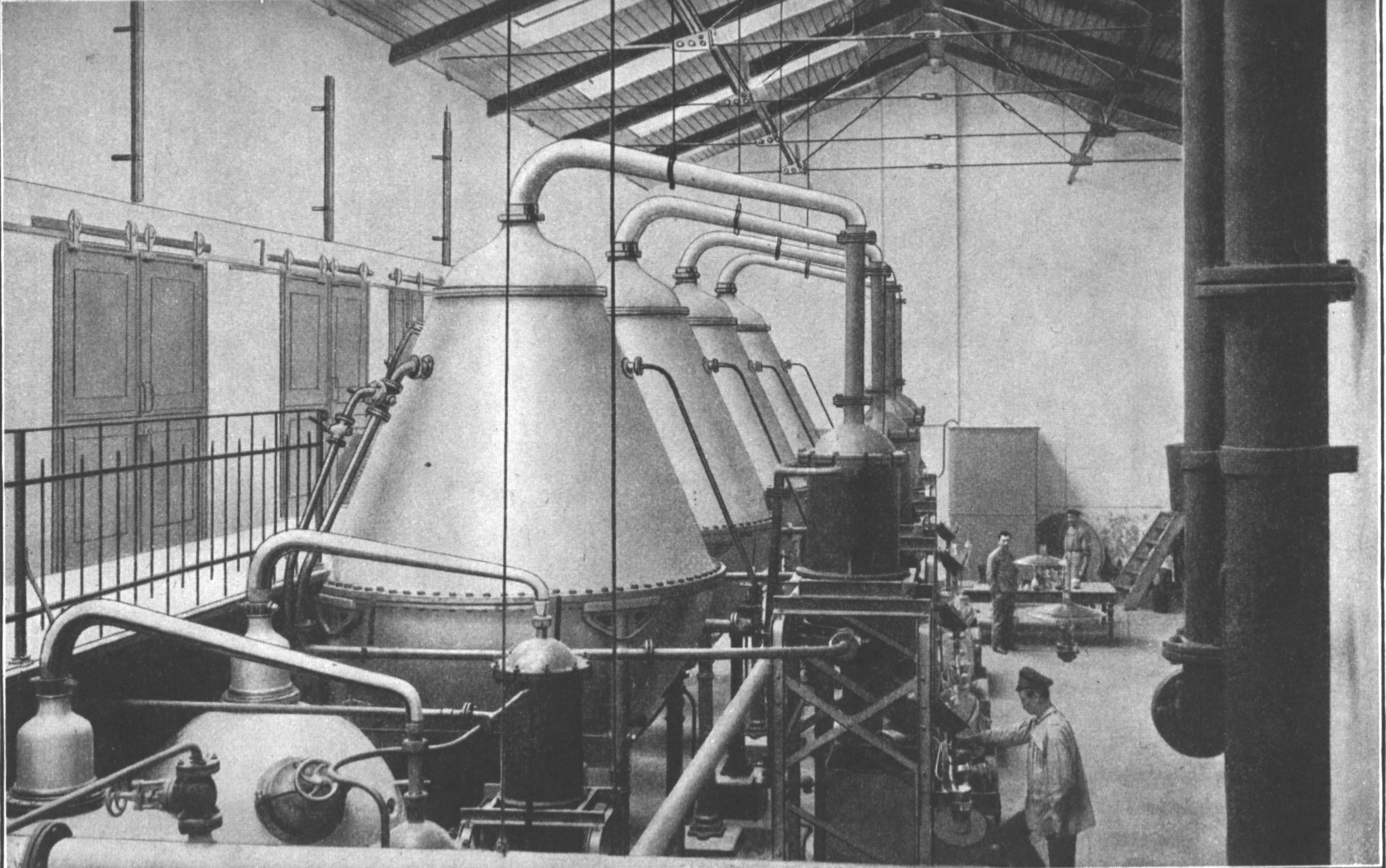

2. Indirect fire, use of a steam generator:

It was the German company Schimmel & Company from Leipzig that used for the first time exclusively indirect steam to distill lavender in Barrème

Haute Provence (route Route Napoleon). They did not invented it but did studies proving the superior quality and yield compared to the old techniques

Some recent steam generators, used by small scale working distillers, France.

3. The history off the cooling system:

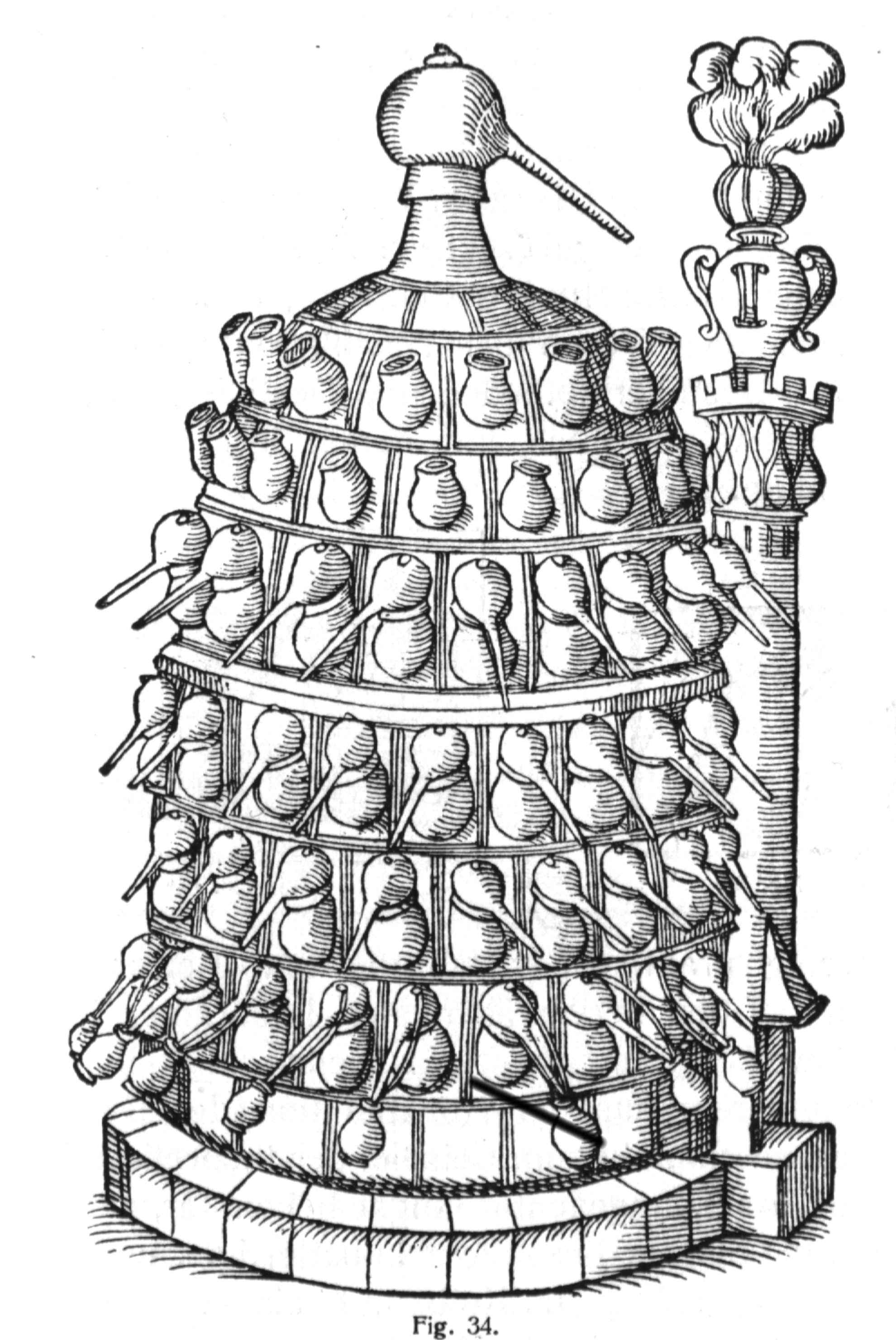

The cooling system was developed in different steps, not always in a logical way, since nature was used as a example for the different devices…

depending on some believe systems…

Some very extravagant systems were developed…

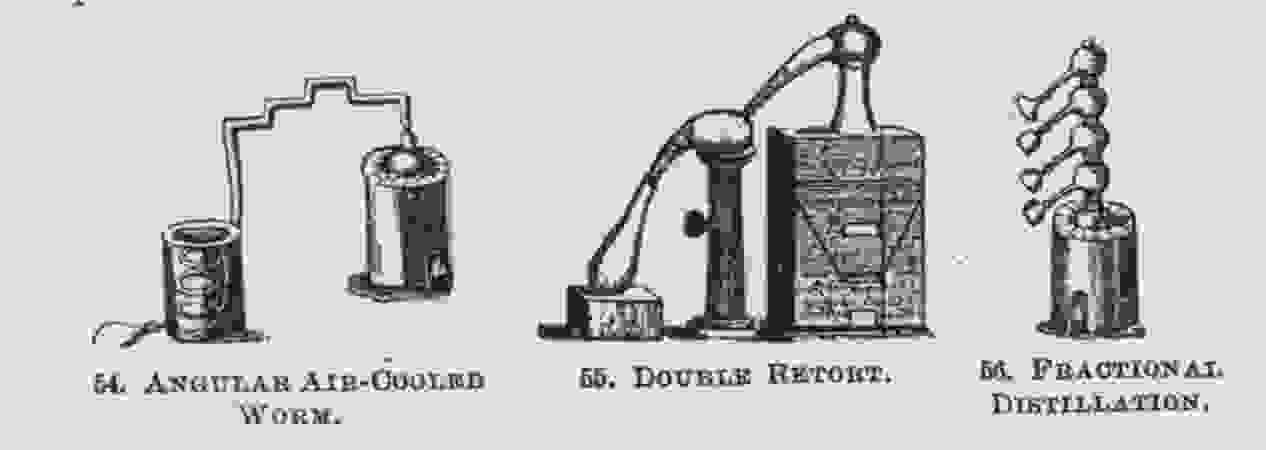

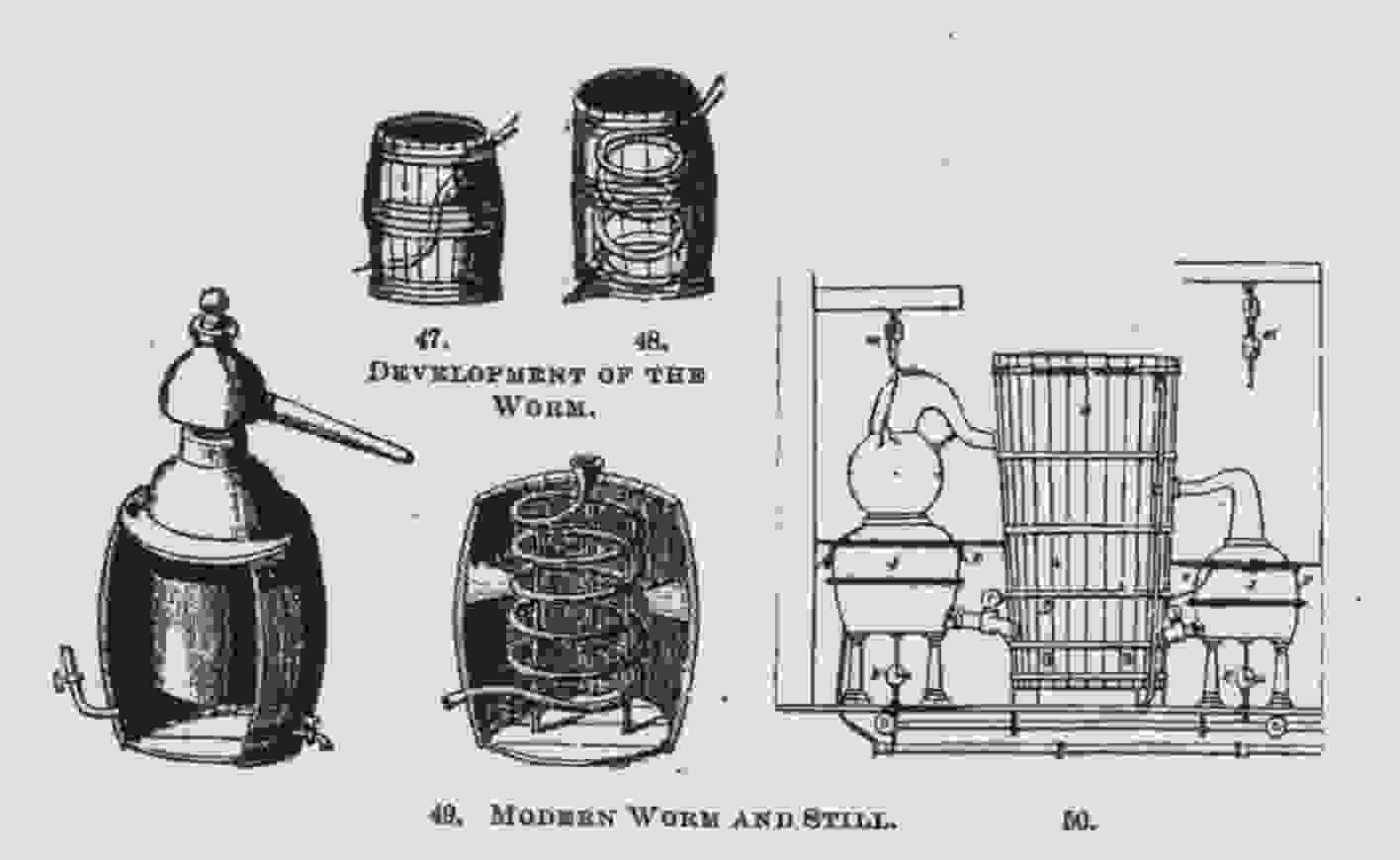

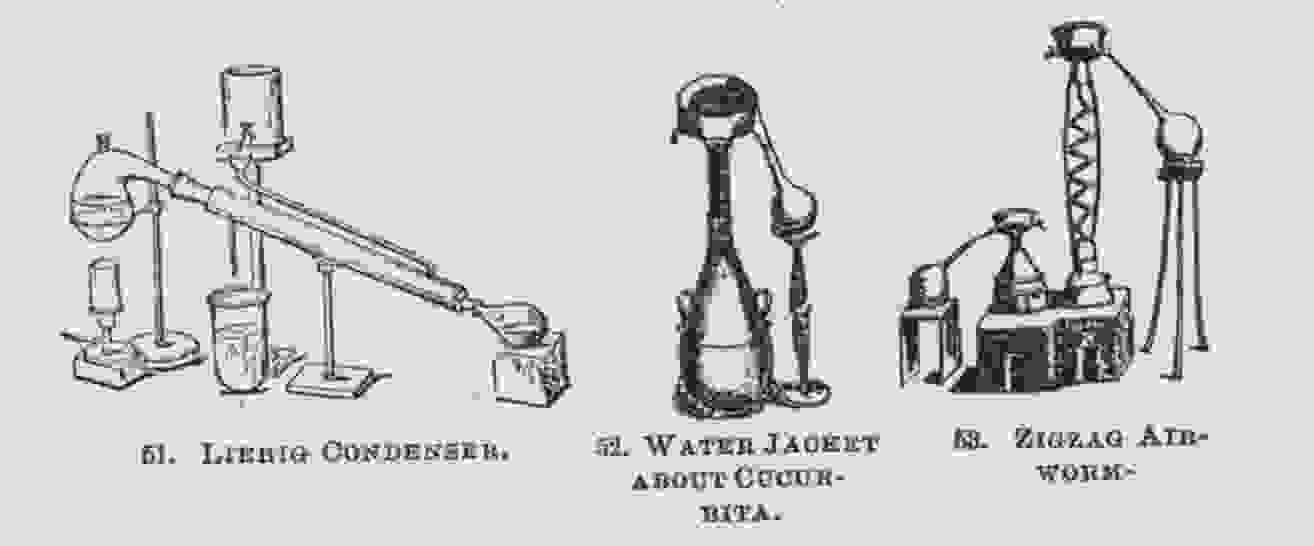

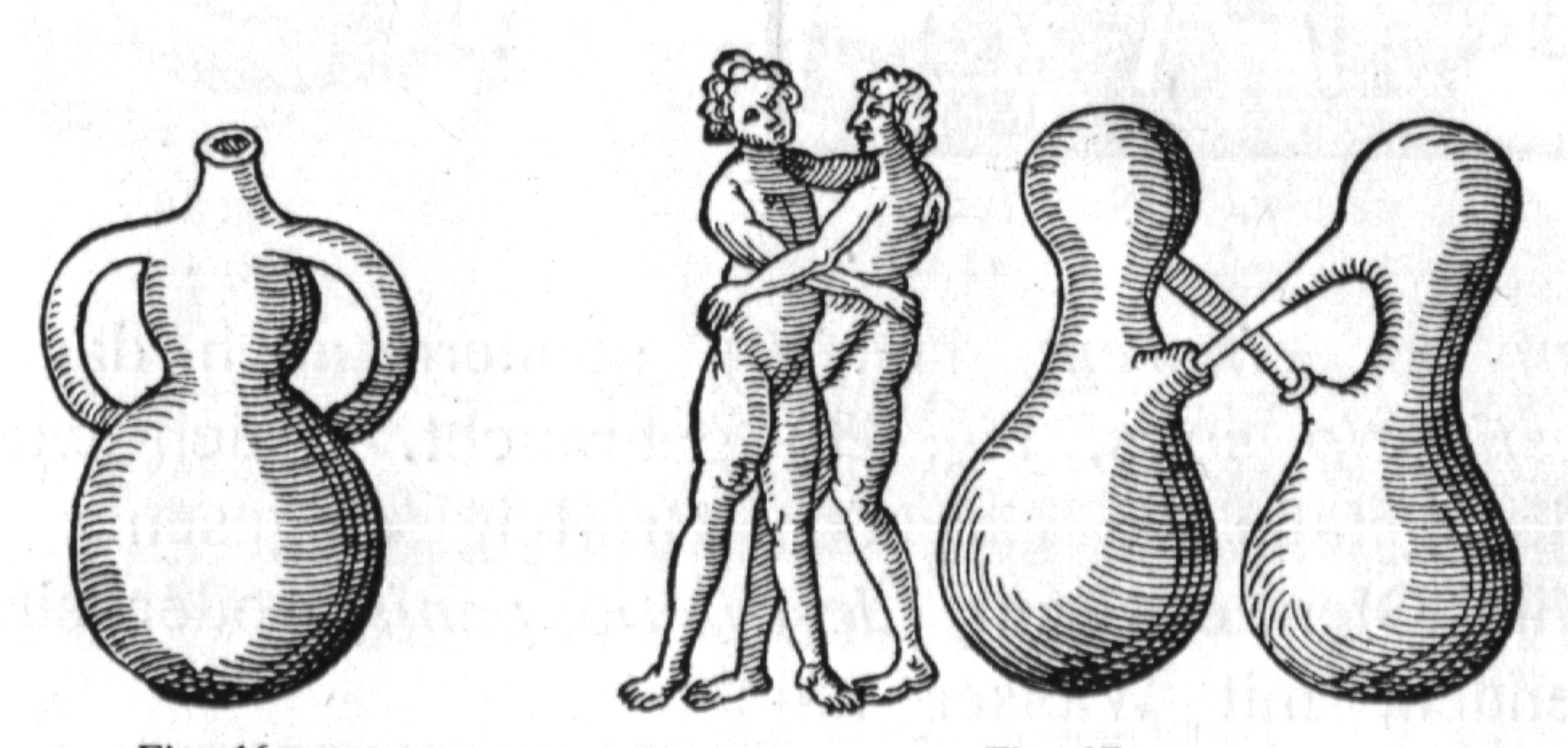

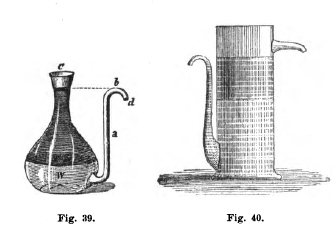

Some old illustrations show the evolution of the techniques:

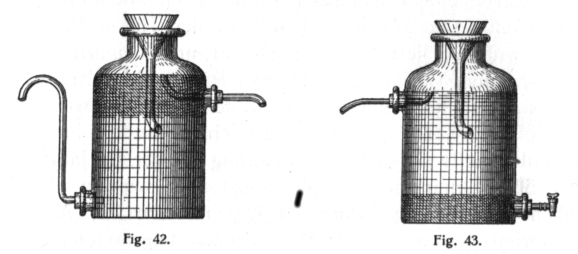

“Modern” cooling systems (end of the 19 Th Century)

Cooling systems of two Hydro diffusion alembics: the steam comes from above and is cooled through the rectangular tubes (cold water passes through the tubes)

Classic cooling systems.

Cooling systems for small lab or home distillation stills

4. The Florentine vessel or separator:

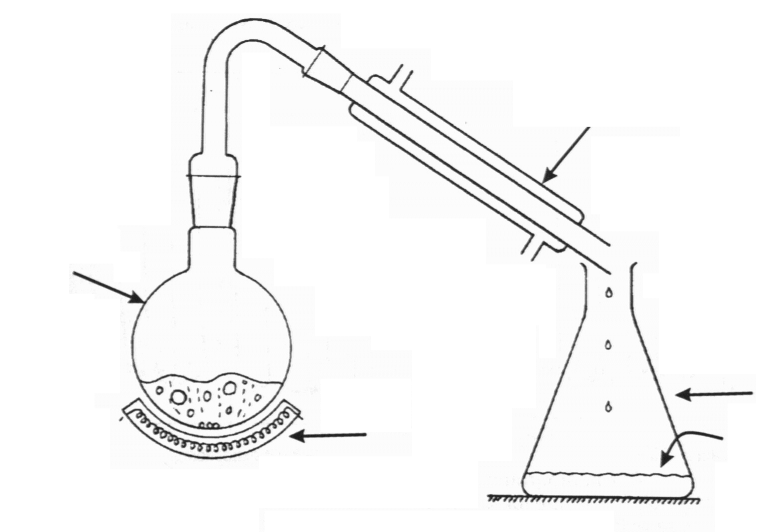

The separation of the two products of distillation is done with a so called Florentine vessel. There are different variations and techniques, all based on the fact that essential oils are not water soluble: they are floating (most cases), or they are heavier than water. We are thus separating the water from the essential oil.

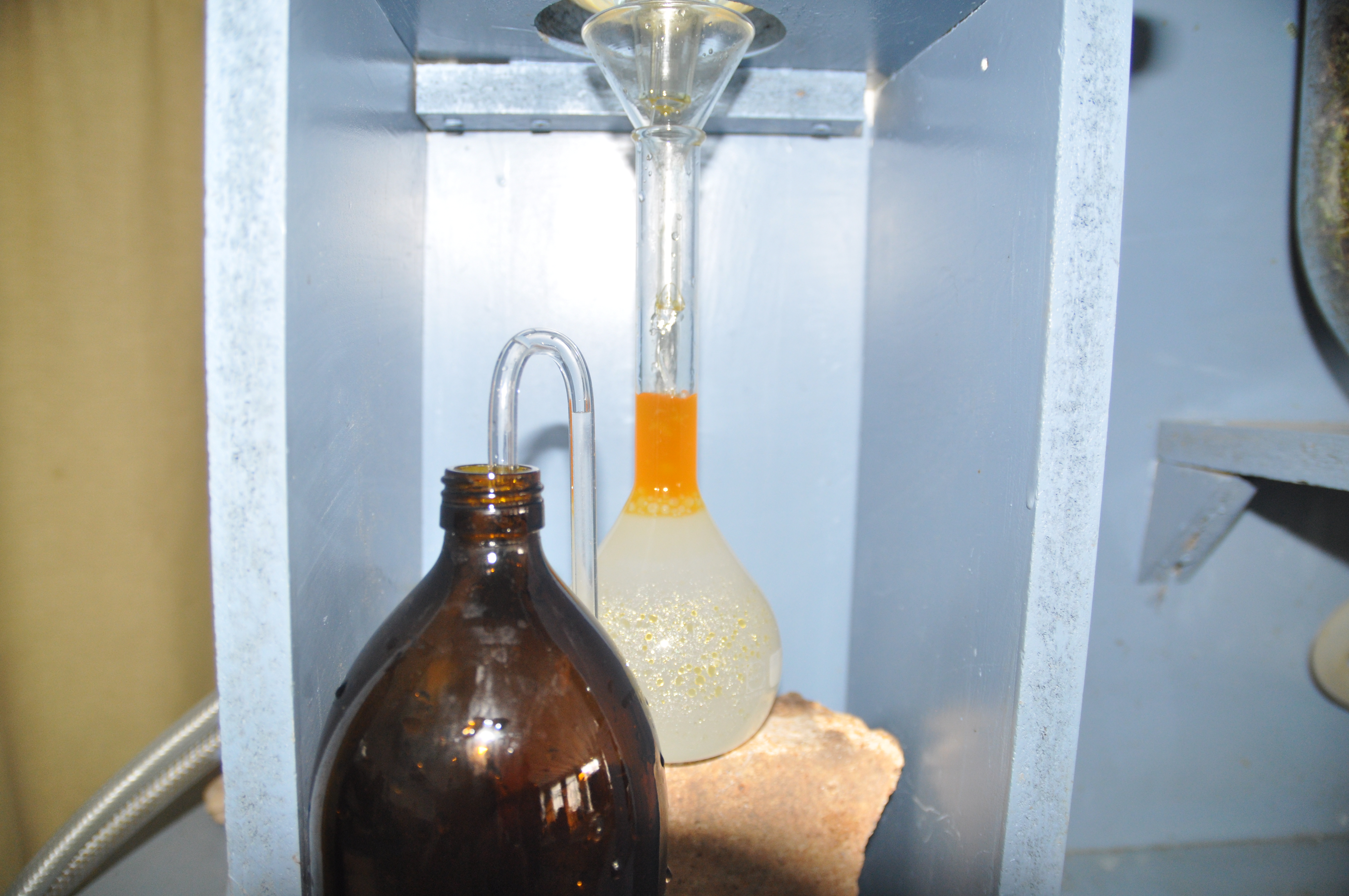

Two types of essential oils: on the left one used for lighter than water essential oils , on the right the vessel used to separate heavy essential oils (cinnamon, wintergreen, vetiver, patchouli, cloves)…

My own small scale glass distillation unit.

Modern Florentine vessels, own production, last image: a Florentine vessel for the heavy oils.

Separating essential oils: final step: condenser, waiting until water and essential oils are separated, then first removing the water and finally collecting the essential oil.